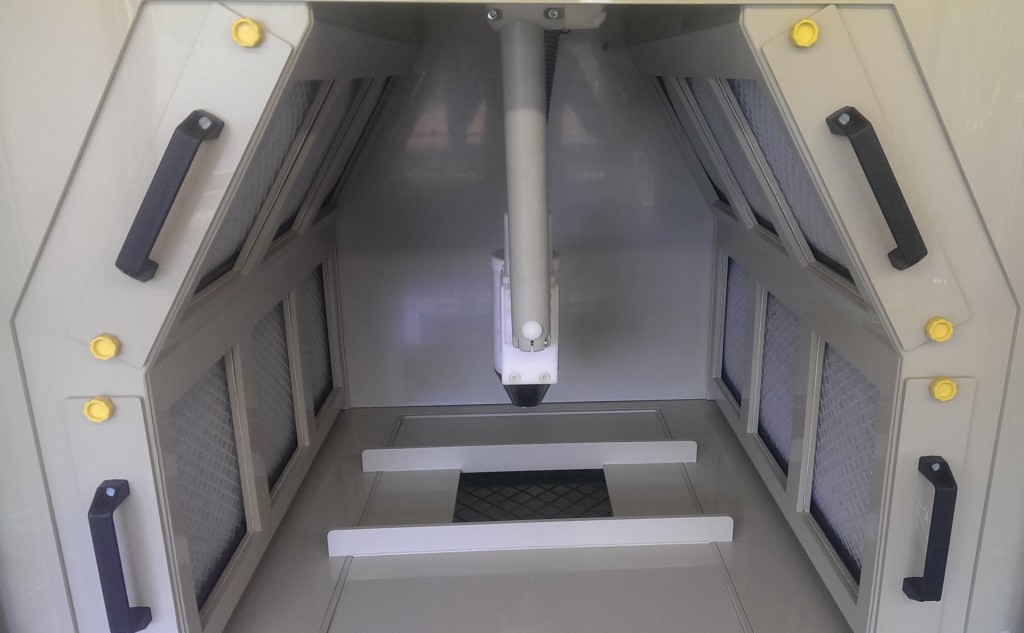

Nanofiber Spinning Unit

compact machine with high and constant output

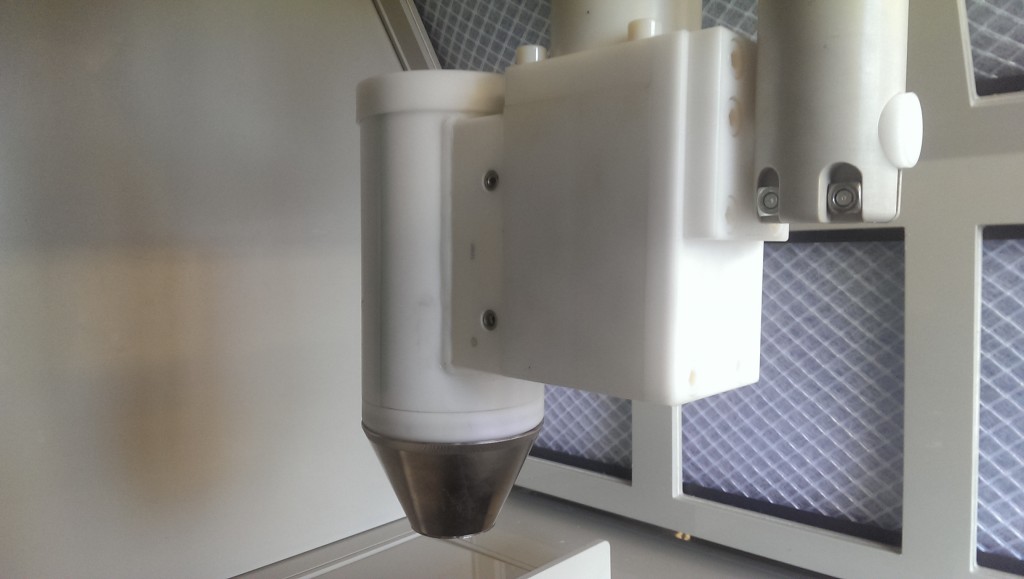

The DIENES Nanofiber Unit combines the centrifugal and electrospinning process. This leads to a powerful machine with constant nonwoven quality. Due to a closed system, the dope concentration is stable. The throughput is controlled by a gear pump. That means that the fiber properties and thus the nonwovens quality can be adjusted to the required final product and aren’t affected by the filling level or other external factors. The combination of centrifugal forces and an electrostatic field results in fine single filaments down to 80 nm at a high troughput of up to 22 l/h.

Advantages

- compact space-saving design

- high throughput due to fast spinning centrifuge and dope feeding by gear pump

- filament diameters down to 80 nm

- constant process conditions due to constant dope concentration

- automatic cleaning run at shut down

Available Options

- unwinding and winding device for continious process

- parts in contact with product with improved corrosion resistance for use of aggressive solvents such as formid acid

- intrinsic safe execution of the spinning chamber (explosion protection)

- integrated suction and filter system to exhaust the solvent-soaked air

- transport device for substrate and nanofiber web to avoid tension on the web

- spinning head mounted on a roboter arm to coat three-dimensional elements

Further Information

For detailed information, please contact our sales team.